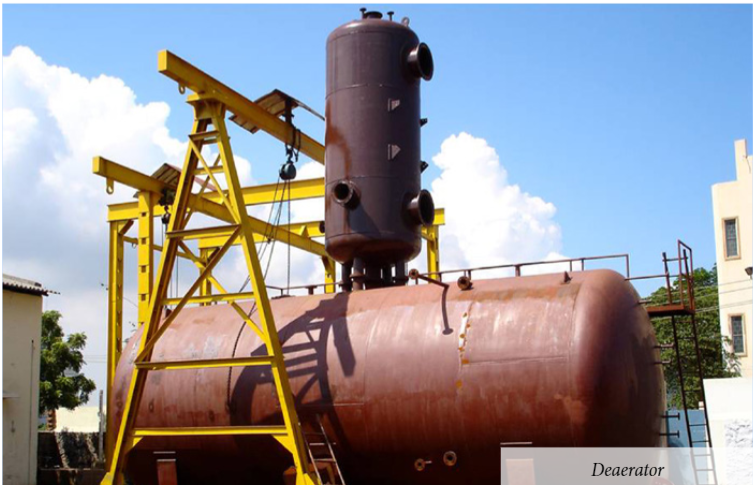

Spray Cum Tray Type Deaerator

We have designed, manufactured and supplied as per ASME, HEI, and IS code of practice, more than 245 Deaerators from 6,000 kg/ hr to 595,000 kg/hr and feed water temperature at the outlet of Deaerator ranging from 105 degree C to 182 degree C to all boiler manufactures and also to the power industries in India and abroad.

For proper functioning of any deaerator choosing the right design based on dissolved oxygen and feedwater temperature at the outlet is very important

Deaerator is used to remove dissolved gases from boiler feed water to enable production of high quality of steam for power generation and process requirement.